Main Business

- Production line

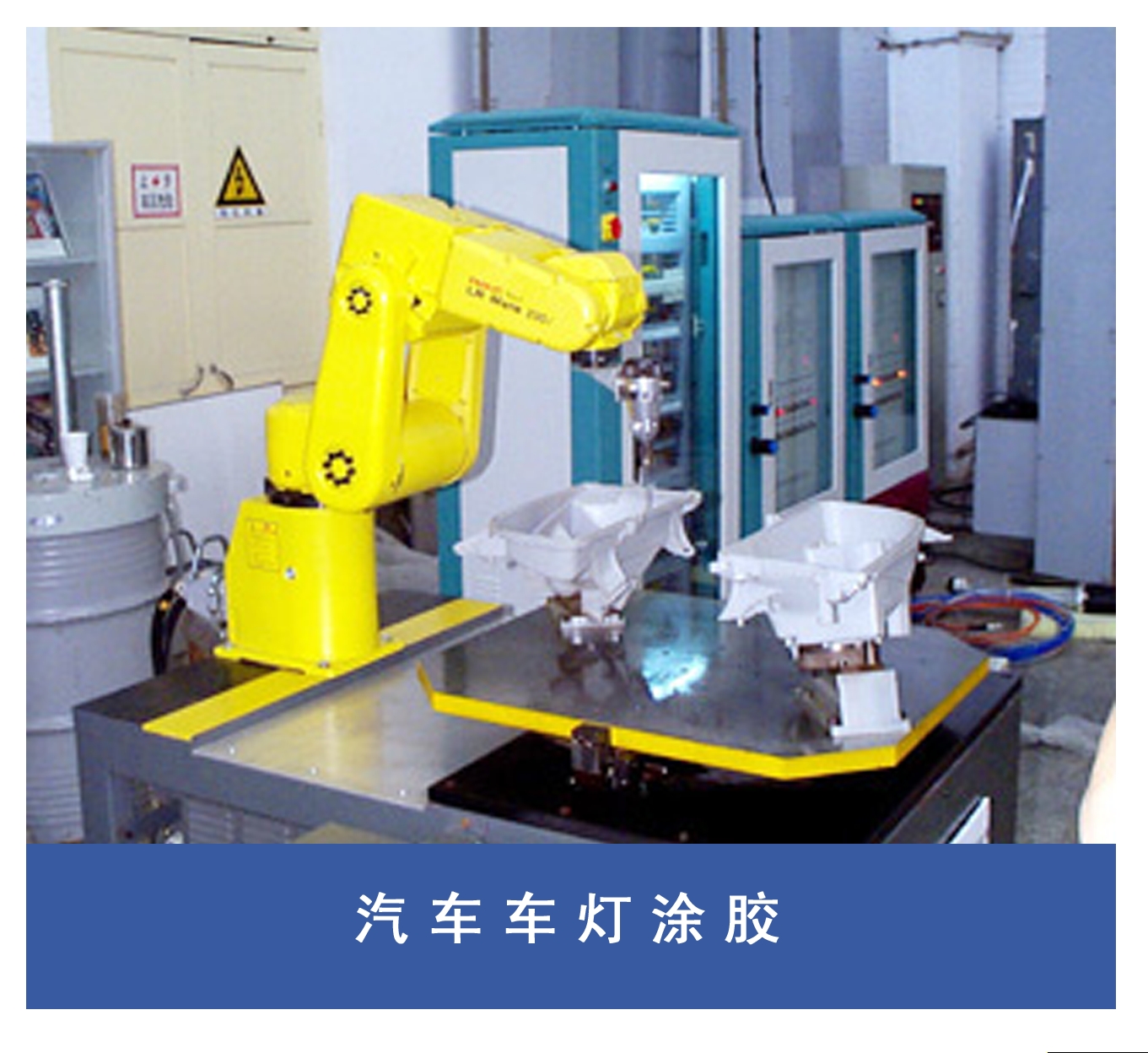

- Intelligent device

- Logistics and warehousing

- Intelligent Factory and Intelligent Park

- Intelligent system

-

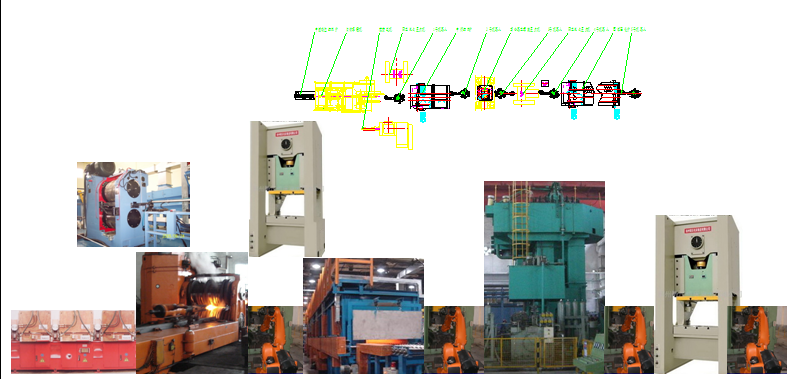

1. Automatic Forging Line for Al parts

The automatic forging line for Aluminum alloy parts consists of forging roll, cross roll, clutch-operated screw press, robots and automatic control system, which can help you in producing high quality Al forging parts.

-

2. Automatic Production Line for Axle Beam & Crank Shaft

A new energy and material saving technology for front axle manufacturing. By adopting accurate roll forging process, the tonnage of main press can be reduced material utilization ratio can be increased for about 15%. 30lines have been set, another 5 in construction.

-

3. Automatic Forging Line for Steering Knuckle

Combined processes of extrusion and forging

are accepted in steering knuckle production:

-- material utilization ratio: 86-88%

-- production efficiency: 30-60sec/piece.

-

4. Heat treatment production line for steel-sheet pressure quenching

Hardening heat treatment of armor plate, ordinary steel plate, aluminum plateand glass.

Including: feeding system, heating furnace, quenching machine, mold, discharge system, cooling system;

Capacity: hardening heat treatment of high-strength plate, templet, swage plate;

Heat source: gas or electricity;

Specialties: after treating plate with high strength, flatness, uniform hardness, less distortion; swage plate with good one-time quenching forming; operating automatic and stable

-

5. Induction heating heat treatment production line

The line is mainly used for treating or surface hardening of long stem parts like drill stem,drill pipe, pump pipe of petroleum industry and drill rod of mining machinery.

Characteristics:

Annealing, quenching for long rod parts or parts after welding

Induction heating power system:KGPS、IGBT100Kw、160Kw、250Kw

Heat source: induction heating, gas heating or hybrid heating;

Including: feeding system, quenching system, tempering system, discharge system;

Application: distortion-control hardening treatment of oil special tube, fine rolling rebar, and automotive rack;

specialties: precise control of distortion, high quality, induction heating or hybrid electricity/ natural gas heating, environmental protection, high thermal efficiency, less oxide, high degree of automation, high productivity.

-

6. Heat treatment production line for front axle beam, crankshaft

The high capacity and effectiveness line is especially for quenching & tempering front axle beam, crankshaft and other forging parts. Daily throughput is 200 pieces or 20 tons.

Characteristics:

Suspending roof and heater drawer structure: easy in maintenance

Puller and conveyer combined transferring system: more reliable

Quenching medium can be easily replaced

Main Specifications:

Size: 33000×3000×2000mm

Power: 850kW

Temperature: 850℃

Capacity: 1100 kg/hr

Feeding speed: 1~10sec adjustable

Application:

Quenching & tempering for front axle beam, crankshaft and other forging parts

-

7. Large Intermediate Frequency Induction Heating Pipe Production Line

Including Ф1626 induction heating pipe bender, Ф1422 induction heating pipe production line, Ф1200 induction heating pipe bender, Ф1016 induction heating pipe production line, Ф864 induction heating pipe bending machine, outside scaling equipment and outside coating equipment. It is the first pipe bender fully automated process control, process management and full heating technology, is currently the largest size, highest degree of automation of pipe unit, with independently sets of intellectual property core technology of the most advanced large-scale intermediate frequency induction heating pipe production line, won the third prize of Science and Technology of China Machinery Industry. And it has been applied in project of Second transporting natural gas from west to east and from Sichuan to east.

-

8. High-pressure Large-diameter Thick-walled Pipe Production Line

Including the forging operation, automatic welding positioner, cutting-edge machine. It uses advanced computer simulate machining process integrated with the traditional moulded hot-forming technology, heat treatment technology and welding technology, products X80 steel grade φ1422 × 60 and the following large-diameter thick-walled pipe fittings used in oil and natural gas pipelines, including tee, elbow, increaser and pipe cap four products. The line is the only mechanized pipe production line, filled in the blank above Ф1219mm diameter thick-walled large diameter pipe line. It has been successfully applied Second West to East Gas Pipeline Project.

-

9. Automation Equipment for Metal Sheet Processing

We has been engaged in the research, development and application of complete set pf metallurgic automation equipment, successfully developed many large metallurgic automation equipment, including: color roll coating production line for strip steel, hot dip galvanizing production line for steel strip, stannum/chromium plating production line for strip steel, hot dip galvanized Zn-Al production line for strip steel, transverse shear production line for strip steel, push—pull pickling unit, non-stainless steel bright annealing line, non-stainless steel annealing and pickling production line, finishing machine for galvanizing production line of steel strips, successfully applied in the enterprises of metallurgy, building materials, household electrical appliance, automobile sectors, and created lots of economic benefits for the enterprises.

Color roll coating production line for metal sheets

Stannum plating production line for strip steel

Chromium plating production line for strip steel

Continuous hot dip galvanizing production line for steel strip

Continuous hot dip galvanizing production line for steel strip chromium plating production line for strip steel

China Academy of Machinery Science and Technology (CAM), founded in 1956, is...

micro-blog

Copyright China Academy of Machinery Science & Technology  Support:xinocheng

Support:xinocheng